LUBRIZOL - USA

SK CHEMICALS - Korean

HEXION - USA

TPR Compounds

EVA Functional Foaming Masterbatch and Additives

© Copyright 2017 Philland International Co., Ltd 粤ICP备19061256号 Powered by www.300.cn

Philland International Co., Ltd

Add:4F-1, No. 366 Changchun Road, Zhongshan District, Taipei City Taiwan Province (10487)

Tel: 886-2-27175501

Fax:886-2-27175502

E-mail:sales.taipei@philland.net

Who’s Philland Agent Service Center Contact us

SK Chemicals- Korea

SK Group is one of the three largest enterprises in South Korea who mainly engages in energy chemicals, information/communication industry. These 2 subsidiaries under SK group are listed on Global 500.SK Chemicals Co., Ltd, a company belongs to SK group is committed to energy chemical & life science. In the end of 2005, SK Chemicals had set up SK Chemicals (Suzhou) Co., Ltd. to develop business in China. We are core agent of Ecozen®,Skygreen®,Skypel®,Skypet® ,Skypura®Skytra®,Ecotran® series products and so on.

Application:

ECOZEN is a new product which is combined with biotech and chemical technology by SK Chemicals. Its HDT is higher than general PETG with better transparency compared to PC as well as excellent chemicals resistance and impact resistance.

ECOZEN Properties

|

Test Items |

Unit |

T90 |

T95 |

T110H/YF300 |

T120 |

|

Heat Distortion Temperature |

℃ |

80 |

85 |

100 |

109 |

|

Tensile Strength @ Yield |

Kgf/cm2 |

530 |

530 |

520 |

550 |

|

Tensile Strength @ Breake |

Kgf/cm2 |

480 |

340 |

450 |

470 |

|

Elongation @ Yield |

% |

5.8 |

5.7 |

6.8 |

6.8 |

|

Elongation @ Break |

% |

230 |

150 |

150 |

110 |

|

Flexural Strength |

Kgf/cm2 |

840 |

880 |

890 |

1000 |

|

Flexural Strength |

Kgf/cm2 |

20400 |

21700 |

22200 |

21700 |

|

Izod Impact Strength Notched @ 23 ℃ |

J/m |

N.B. |

N.B. |

N.B. |

N.B. |

|

Rockwell hardness |

|

115 |

115 |

119 |

121 |

SKYGREEN Properties

|

Test Items |

Test Methods |

Unit |

S2008 |

K2012 |

KN200 |

PN200 |

JN200 |

|

|

Thickness test |

- |

Mm |

- |

3 |

3 |

- |

- |

|

|

Specific Gravity |

ASTM D792 |

- |

1.27 |

1.27 |

1.27 |

1.27 |

1.23 |

|

|

Mold shrinkage |

ASTM D955 |

% |

0.3-0.6 |

- |

- |

0.2-0.5 |

0.2-0.5 |

|

|

Rockwell hardness |

ASTM D785 |

R-scale |

110 |

116 |

116 |

105 |

105 |

|

|

Water Absorption (24h soaking) |

ASTM D570 |

% |

0.13 |

0.2 |

0.2 |

0.13 |

0.13 |

|

|

Mechanical Property |

||||||||

|

Tensile strength 50mm/min |

ASTM D638 |

Mpa |

50 |

53 |

53 |

50 |

45 |

|

|

Tensile strength@yield 50mm/min |

ASTM D638 |

Mpa |

28 |

26 |

26 |

26 |

53 |

|

|

Elongation Break 50mm/min |

ASTM D638 |

% |

140 |

70 |

70 |

120 |

340 |

|

|

Flexural Modulus 1.27mm/min |

ASTM D790 |

Mpa |

2100 |

2150 |

2150 |

2150 |

1800 |

|

|

Flexural Strength 1.27mm/min |

ASTM D790 |

Mpa |

73 |

80 |

80 |

71 |

80 |

|

|

Izod Impact Strength Notched @ 23 ℃ |

ASTM D256 |

J/m |

100 |

90 |

90 |

85 |

NB |

|

|

Thermal Property |

||||||||

|

Heat Distortion Temperature @ 0.455 MPa / @ 1.820 MPa |

ASTM D648 |

℃ ℃ |

70 64 |

74 70 |

74 70 |

70 62 |

74 64 |

|

|

Vicat softening temperature |

ASTM D1525 |

℃ |

85 |

83 |

83 |

- |

88 |

|

|

Glass transition temperature |

DSC method |

℃ |

- |

- |

- |

- |

- |

|

|

Optical Property |

||||||||

|

Haze |

ASTM D1003 |

% |

- |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

|

Transmittance |

|

|

- |

89 |

89 |

90 |

89 |

|

|

Refractive index |

ASTM D542 |

- |

- |

1.57 |

1.57 |

- |

- |

|

|

Electrical Property |

||||||||

|

Insulating strength (instantaneous, restoring rate at 500v/sec) |

ASTM D149 |

KV/mm |

16 |

16 |

- |

16 |

- |

|

|

Surface resistance |

ASTM D257 |

Ohm |

1016 |

1016 |

1016 |

- |

1016 |

|

Application:

SKYGREEN is a noncrystalline copolyester with good chemical resistance and stress blushing resistance. Up to 91% transparency index as organic glass, Skygreen® has superior impact strength over PC, which is suitable for injection molding, extrusion and EBM process.

SKYGREEN applications: Packaging for cosmetics, medicine and transparent medical devices, brushes and personal care products, pens and stationeries, electrical appliance and transparent parts for household appliance, toys, daily commodities, lamps, blowing bottles, transparent pipes and profiles, films, sheets and panels.

Application:

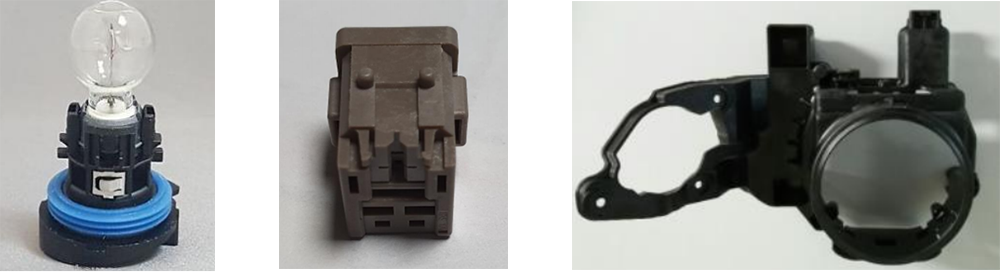

SKYPEL combines the features of engineering plastics and rubbers, creating a new application for traditional engineering plastics. SKYPEL is high performance engineering plastic with unparalleled flexitility, resilience, flexure fatigability under low temperature, oil resistance, grease resistance and resistance of a number of other chemical solvents and industrial chemicals.

SKYPEL Properties

|

Test Items |

Test Methods |

Unit |

G130D |

G140D |

G155D |

G163D |

G168D |

G172D |

G182D |

|

Hardness |

ASTM D2240 |

Shore D |

30 |

40 |

55 |

63 |

68 |

72 |

77 |

|

Specific Gravity |

ASTM D792 |

* |

1.07 |

1.16 |

1.18 |

1.21 |

1.24 |

1.25 |

1.27 |

|

Moisture |

ASTM D570 |

% |

0.8 |

0.6 |

0.5 |

0.3 |

0.3 |

0.3 |

0.2 |

|

Mold Shrinkage |

ASTM D955 |

% |

0.4 |

0.8 |

1.2 |

1.5 |

1.6 |

1.7 |

2.2 |

|

5% Tensile strength |

ASTM D638 |

Kgf/cm2 |

6 |

24 |

65 |

110 |

150 |

230 |

300 |

|

10% Tensile strength |

Kgf/cm2 |

18 |

44 |

115 |

175 |

240 |

300 |

400 |

|

|

Tensile strength |

Kgf/cm2 |

220 |

270 |

400 |

440 |

460 |

470 |

500 |

|

|

Elongation @ Yield |

% |

900 |

680 |

600 |

500 |

450 |

420 |

350 |

|

|

Flexural modulus |

ASTM D790 |

Kgf/cm2 |

280 |

680 |

2100 |

3200 |

4700 |

5500 |

9000 |

|

Tear strength |

ASTM D1004 |

Kn/m |

95 |

115 |

165 |

180 |

193 |

205 |

260 |

|

Heat Distortion Temperature |

ASTM D256 |

Kgf./cm |

N.B. |

N.B. |

N.B. |

N.B. |

23 |

12 |

4 |

|

Vertical resilience |

ASTM D2632 |

% |

72 |

57 |

55 |

53 |

47 |

* |

* |

|

Softening point |

ASTM D3418 |

℃ |

174 |

155 |

202 |

212 |

215 |

218 |

222 |

|

Heat Distortion Temperature |

ASTM D648 |

℃ |

* |

70 |

105 |

130 |

140 |

150 |

156 |

|

Flow index |

ASTM D1238 |

g/10min |

18 |

7 |

20 |

10 |

13 |

13 |

8 |

|

Testing temperature |

℃ |

220 |

190 |

220 |

230 |

230 |

230 |

230 |

SKYPET is an effective low crystal copolymerization copolyester. As a new product, SKYPET prossess excellent ductibility and chemical erosion resistance, which can be applied in wide range of injection molding and sheets extrusion.

SKYPET Property

BR8040

|

Test Item |

Test Method |

Unit |

Tested Value |

|

Viscosity |

SK chemical |

Dl/g |

0.80±0.02 |

|

Melting temperature |

DSC |

℃ |

236±2 |

|

Glass transition temperature |

|

℃ |

79 |

|

Density |

ASTM D1505 |

g/cm2 |

1.40±0.01 |

|

Volume density |

ASTM 1895 |

Kg/ m2 |

820-900 |

|

Chroma |

SK chemical |

- |

Max.1 |

|

Moisture |

Karl-Fischer method |

Wt% |

Max.0.5 |

BRV

|

Test Item |

Test Method |

Unit |

Tested Value |

|

Specific Gravity |

ASTM D792 |

- |

1.34 |

|

Water Absorption (24h soaking) |

ASTM D570 |

% |

<0.3 |

|

Bulk density |

ASTM D1895 |

Kg/ m3 |

820-900 |

|

Crystal density |

ASTM D1505 |

g/m3 |

1.4 |

|

Tensile strength @ Yield |

ASTM D638 |

Mpa |

60 |

|

Tensile strength @ Break |

Mpa |

25 |

|

|

Elongation @ Break |

% |

>50 |

|

|

Flexural strength |

ASTM D790 |

Mpa |

83 |

|

Flexural modulus |

ASTM D790 |

Mpa |

2500 |

|

Izod Impact Strength Notched @ 23 ℃ |

ASTM D256 |

J/m |

35 |

|

Heat Distortion Temperature |

ASTM D648 |

℃ |

69 |

|

Haze |

ASTM D1003 |

% |

<1.0 |

|

Melting temperature 279℃ |

Capillary rheometer |

poise |

490 |

SKYPURA Property

|

Test Item |

Test Method |

Test condition |

Unit |

SKYPURA 7100 I |

SKYPURA 7100 S |

SKYPURA 7100 T |

|

Physical Property |

||||||

|

Specific Gravity |

D792 |

23℃ |

g/c m3 |

1.160 |

1.178 |

- |

|

Melt Index |

- |

300℃/1.2kg |

g/10min |

4 |

24.5 |

44 |

|

Transparency/Haze |

- |

- |

- |

23/92 |

- |

82/22 |

|

Mechanical Property |

||||||

|

Tensile strength |

D638 |

50mm/min |

Kgf/ c m2 |

490 |

560 |

590 |

|

Elongation |

D638 |

50mm/min |

% |

145 |

80 |

90 |

|

Flexural strength |

D790 |

2.8mm/min |

Kgf/ c m2 |

615 |

780 |

780 |

|

Flexural modulus |

D790 |

2.8mm/min |

Kgf/ c m2 |

15,000 |

17,600 |

17,800 |

|

Impact strength |

D256 |

1/8’’Notched,23℃ |

J/m |

730 |

680 |

710 |

|

|

|

1/4’’Notched,23℃ |

J/m |

430 |

140 |

120 |

|

|

|

1/8’’Notched,-30℃ |

J/m |

580 |

- |

- |

|

Thermal Property |

||||||

|

Heat Distortion Temperature |

D648 |

1.8MPa |

℃ |

112 |

114 |

113 |

Application:

SKYPURA is a new product with better chemical resistance, low hygroscopicity and good impact resistance under low temperature. It can be used in automobile radiator and door grip, etc.

SKYTRA FR PET/GF 5220F

|

Injection Property |

|||

|

Tensile strength @ Yield |

ASTM D638 |

Kgf/ c m2 |

1,430 |

|

Elongation @ Break |

ASTM D638 |

% |

1.9 |

|

Tensile modulus |

ASTM D638 |

Kgf/ c m2 |

106,600 |

|

Flexural strength |

ASTM D790 |

Kgf/ c m2 |

2,000 |

|

Flexural modulus |

ASTM D790 |

Kgf/ c m2 |

112,000 |

|

Impact strength Notched 3.2mm@23℃(73℉) |

ASTM D256 |

J/m |

75 58 |

|

Thermal Property |

|||

|

Heat Distortion Temperature @1.82Mpa |

ASTM D648 |

℃ |

215 |

|

Flammability @0.8mm @1.5mm |

UL94 |

- |

V-0 V-0 |

|

Physical Property |

|||

|

Specific Density |

ASTM D792 |

g/cc |

1.68 |

|

Moisture absorption |

ASTM D570 |

% |

0.15 |

|

Water absorption |

ASTM D570 |

% |

0.75 |

|

Melt index @2.16kg @5.00kg |

ASTM D1238 |

g/10min |

16 42 |

|

Mold shrinkage MD(flow) TD(cross-flow) |

ASTM D955 |

% |

0.15 0.80 |

|

Electrical Property |

|||

|

CTI |

UL 746 |

|

PLC 4 |

|

CTI |

IEC 60112 |

voit |

200 |

ECOTRAN PPS

ECOTRAN PPS is a special engineering plastic with high performance to replace metal. It has excellent thermal stability ,chemical resistance, outstanding mechanical property, inherent flame retardancy, good dimensional stability and other characters.

|

Test Item |

Test Method |

Unit |

E1040G |

E1040S |

E5070G |

|

|

|

|

40% Glass fibres General |

40% Glass fibres high strength |

Glass minerals General |

|

Physical Property |

|||||

|

Density |

ISO 1183/A |

- |

1.66 |

1.67 |

1.98 |

|

Hygroscopicity |

ISO 62 |

% |

0.02 |

0.02 |

0.02 |

|

shrinkage(MD/TD❶) |

INITZ Method❷ |

% |

0.3/0.7 |

0.3/0.7 |

0.3/0.6 |

|

Mechanical Property |

|||||

|

Tensile strength |

ISO 527-1,-2 |

Mpa |

175 |

200 |

135 |

|

Elongation |

ISO 527-1,-2 |

% |

1.6 |

1.8 |

0.8 |

|

Flexural strength |

ISO 178 |

Mpa |

255 |

270 |

220 |

|

Flexural modulus |

ISO 178 |

Mpa |

13,400 |

13,500 |

22,000 |

|

Charpy Impact strength(Notched) |

ISO 179/1eU |

KJ/m² |

8.5 |

10.0 |

7.0 |

|

Charpy Impact strength(Unnotched) |

ISO 179 |

KJ/m² |

38 |

42 |

18 |

|

Thermal Property |

|||||

|

Melting temperature |

ISO 11357 |

℃ |

280 |

280 |

280 |

|

Heat Distortion Temperature (1.82MPa) |

ISO 75-1,-2/A |

℃ |

265 |

265 |

265 |

|

Flame retardancy |

UL-94 |

Class |

V-0 |

V-0 |

V-0 |

|

Electrical Property |

|||||

|

Insulating strength(T=1.0mm) |

IEC 60243-1 |

Kv/mm |

28 |

28 |

25 |

|

Dielectric constant,1MHz |

IEC 60250 |

- |

3.8 |

3.8 |

4.8 |

|

Dissipation factor,1MHz |

IEC 60250 |

- |

0.0016 |

0.0016 |

0.0016 |

|

Relative leakage tracking index (CTI) |

IEC 60112 |

Volt |

150 |

150 |

225 |

|

Electric strength |

ASTM D495 |

sec |

125 |

125 |

180 |

|

Volume resistivity |

IEC 60093 |

Ohm.cm |

10¹⁶ |

10¹⁶ |

10¹⁶ |

❶MD:machine direction,TD:transverse direction

❷test block:100mm*100mm*3mm